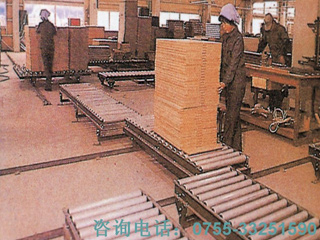

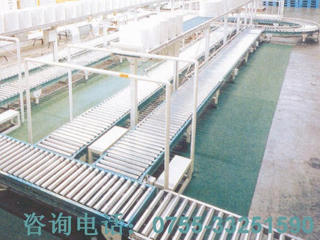

The main components of conveyor belt material are PVC/PU/PE, rubber and cord weaving structure, which can not only improve the quality of conveyor belt, but also ensure the long-term stability of conveyor belt, but also bring economic cost savings for the majority of manufacturers and avoid many troubles in the production line. The main functions of conveyor belt in production line are conveying, drying and assisting in bonding cardboard, so the production process of conveyor belt has become one of the most critical processes to determine the quality of products.

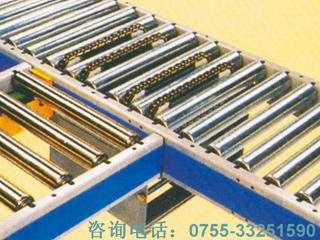

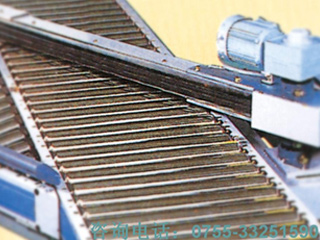

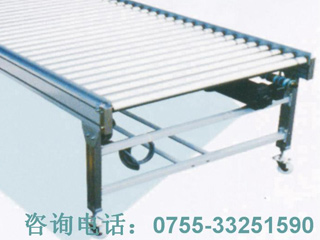

Surface smoothness and firm structure: the requirements of conveyor belts are strong quality, high density, geometrical stability of expansion and contraction, surface insensitivity. The conveyor belts can be kept smooth in long-term use, so that they are not easily affected by residual adhesives and other dirt. At the same time, the strong quality can ensure that the conveyor belts do not come off line and do not lay. Uneven, so that the bonded cardboard will be uniform, flat and more perfect, avoiding the appearance of blisters and other undesirable quality phenomena. Needle-punched conveyor belt and cotton conveyor belt have their own merits. Needle-punched conveyor belt is mainly made of synthetic chemical fibers by needle-punching process. The surface of needle-punched conveyor belt is smooth and soft in the initial stage, which is beneficial to the contact affinity between surface and cardboard. However, the weakness of needle-punched conveyor belt is that its surface is too sensitive, easy to strip, rise and be polluted, and difficult to The grindability is not strong enough, and the expansion geometry is not stable enough. Conveyor belts are mainly made of cotton fibers and synthetic fibers and reinforced with high density, which ensures strong quality and flat surface, thus significantly improving wear resistance and long-term thermal stability.

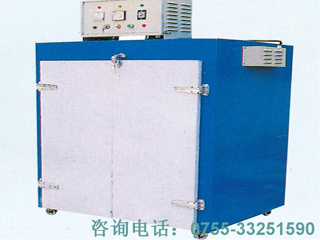

Dryness and permeability: The production process of bonded cardboard requires that the conveyor belt must have the ability to absorb vapor and evaporate moisture. The hygroscopicity and dryness of synthetic chemical fibers are poor, but the porosity of needle-punched belt made of synthetic fibers is higher than that of cotton conveyor belt woven mainly from cotton fibers. It also strengthens its hygroscopicity and evaporation. The physical properties of cotton fibers are more advantageous than that of chemical fibers. According to the relative value of vapor absorption/vapor evaporation, the cotton conveyor belt is obviously higher than the needle-punched conveyor belt. Generally speaking, it has stronger dryness and air permeability.

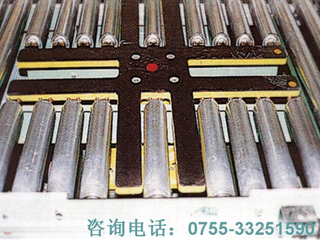

Transfer pull conveying force: the conveyor belt is required to have stronger density, wear resistance and greater friction coefficient; the larger the friction coefficient, the smaller the pressure required for the same transmission pulling force, which can not only reduce energy consumption, but also improve the service life of the conveyor belt and equipment. Compared with ordinary conveyor belts, the surface friction coefficient of shift conveyor belts increases by nearly 20%. The increase of friction coefficient is also helpful for the conveyor belt itself not to deviate, not to slip, and the production performance tends to be more stable. The high density of cotton ribbon fibers also enables the production line to maintain uniformity, uniformity and geometric stability when the width of cardboard is constantly changed and adjusted.